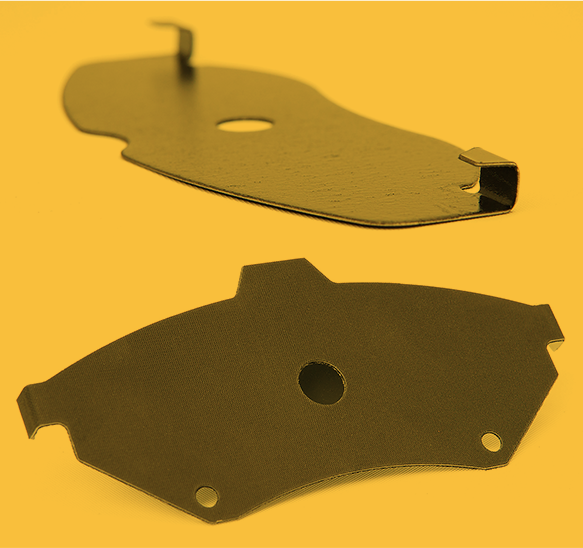

Innovative technology

Based on the solutions of the Swiss, world leader in the production of fast drawing belts – Bruderer company – we have developed a new method of producing shims. We have introduced supervision of semi-finished products manufactured at separate stations.

Complexity

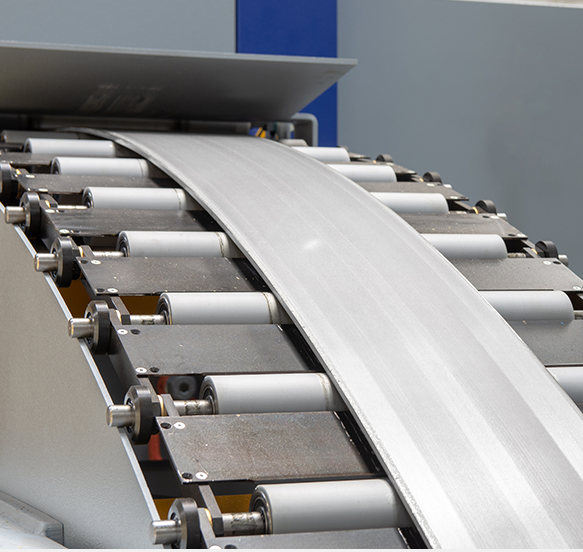

Our new production line has a BSTA 510 press and peripheral equipment, e.g., a unit for unwinding and straightening the material strip at the input, and automatic labeling. Thanks to the developed capabilities of our devices, we constantly raise the standard of our products. As a result, business partners receive a fully functional outcome of the highest quality.

Swiss precision

The accuracy and precision of the final products are ensured by the centric BSTA 510 press, characterized by an extraordinary efficiency of up to 1000 beats per minute. It can adjust the speed depending on the size of the manufactured workpiece. Thanks to continuous monitoring and control of the process, we can maintain production constantly and provide the highest quality products.

Repeatability and quality

We are constantly striving for excellence! Our line for producing anti-squeak overlays is the first solution of this type in the world. In technical terms, our latest products offer better performance than parts installed as factory equipment. No wonder Lumag products meet the expectations of even the most demanding customers.